What A Show

We’d like to say “thank you” to all of the folks that took the time to swing by our booth at the recent SVC TechCon show in Washington DC. It was a pleasure to see all of you there. If you did not make it to the show this year, please don’t let that stop you from contacting us if you have a need for ion beam power supplies, ion sources, grid sets or components. We are happy to provide you with the information and the equipment you need.

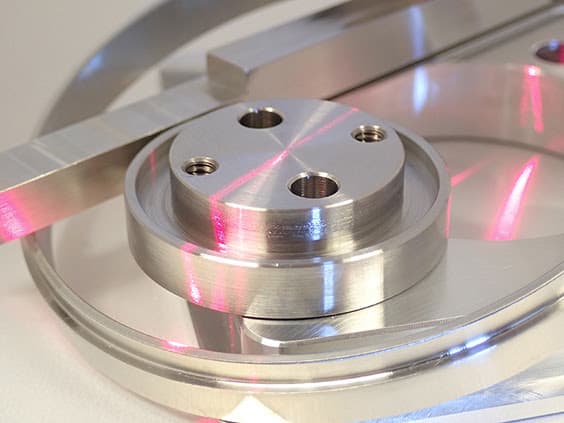

Millennium Machining in full operation

The Millennium Machining machine shop is now in full swing with more new business coming in from around the country. They are still holding a 2-to-3-week lead time for basic machining so get your order in soon. Joe O’Brien and his team are definitely staying on top of things. So, if you’re looking for anything specific for your next project and need machined parts, please reach out to Joe. He is happy to talk with you.

Plasma Process Group has been actively working with Millennium Machining to produce many of our machined ion source and RFN parts used for assemblies. The Millennium Machining team has many years of experience producing quality machined parts using stainless steel and other metals. They have an excellent reputation for top quality and timely delivery. Make them your first choice for machining. You won’t be disappointed.

Please call Joe at 970-833-1983 or send him an email at [email protected]

Tech Tips – RF power and the dreaded E-71

Why does my source keep going out?

You may be aware that E-71, (Error-71), can occur for many different reasons when operating RF ion sources. Historically, the “E-71” is despised by ion source users because it can be generated by so many different ion source problems that are all difficult to diagnose. In this Tech tip, we’ll start off by identifying the most common ones that may have caused the error in your ion source. It is always best to ask yourself, have you recently changed something in the RF circuit? Maybe an RF antenna was replaced, a capacitor changed in the matching network, or a new RF feedthrough installed.

If something was changed, try re-tuning the RF using the standard tuning procedure located in your ion source manual. From experience, this should always be done when something significant has occurred or been changed in your RF circuit. It doesn’t take too long, and it will tell you immediately if there is a short, open circuit, or tuning issue after your change or repair has been made. Even small changes can affect the RF impedance and therefore tuning capability.

If you have not changed anything in your RF circuit and you’re unable to start the source, you should take the time to stop and identify the problem. In some cases, shortly before an E-71 occurs, you may see a brief high reflected power in the RF module. If available, check your data log to your source conditions through your system software. The reflected power can sometimes reach 35 watts when a short has occurred.

A good example of an RF short can be seen in the image of the antenna coils below. This image shows a short to the RF antenna but not to ground. This type of short may actually allow a source to run briefly but the source will not likely tune properly. The overall RF circuit has changed because the RF path has been decreased. If one RF coil is touching the other, your source will not likely tune properly.

If you have an open RF circuit, as if the RF cable is disconnected from the source or power supply, you will likely see a maximum forward power of about 15 watts with about 15 watts reflected power. If your RF starts normally and then the error 71 occurs, the error is generated because something is changing abruptly as the source warms up.

A common failure is a short to ground. This usually does not allow the source to tune, and in some cases, causes reflected power to increase. We would recommend investigating by removing your grid set and looking inside the source for evidence of a parasitic plasma. Please review our previous Tech Tip. If there is no evidence of this, then the next step would be to check outside the ion source. Most shorts outside the source occur at the feedthrough inside the vacuum chamber.

A common RF feedthrough that can short to ground can be seen in the images below. Check under the braided lead shield for burned RF leads between the RF feedthrough flange and the source shroud. If a failure has occurred here, you would see black residue or carbon build up where RF is shorting to ground. Even a frayed wire from the braided shield could cause a short to the RF lead.

You will sometimes see the Teflon beads melted in this location, which can be found inside the shielding that surrounds them. This will require removal of the feedthrough for a more detailed inspection and removal of the shielding. Be aware that this kind of short can cause serious damage to components and your power supply if not addressed. If the source fails to start and run after two attempts, stop and investigate. Look carefully for arc marks, carbon spots or high heat discoloration throughout the RF circuit.

We can’t stress enough, as indicated above, don’t ever attempt to restart the source more than twice in rapid succession when an error 71 occurs. Doing so can cause additional damage to your source, components and/or your power supply. There is an obvious issue somewhere, so take the time to investigate the problem or you will likely cause further damage to your equipment.

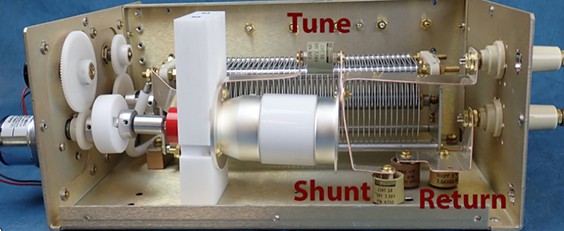

Another issue could be with one of your small capacitors in the matching network. If suspected, turn off the source and power supply and lock them out. Remove the matching network cover to look for a burned or cracked capacitor. See the tune, shunt and return caps in the image below. Normally when they fail, there are visual clues. Severe color change from heat or visible cracks are very common.

If you identify one or more to be damaged, replace them with the same style and size capacitor in the same locations. Also check your straps and strap connections inside and clean them if there are signs of oxidation at connection points. A fine Scotch Brite pad works well for this. Be sure to retune your RF when these repairs or replacements are made.

Here are a few of the common error 71 causes:

- Parasitic plasma coating the antenna insulators conductively. (As discussed in our last Tech Tip).

- Foil or liners touching unshielded RF leads.

- Conductive coating compromises the RF and/or DC leads.

- Gas pressure is too low; the source is starved out.

- Gas pressure is too high creating parasitic plasma.

- Gas flow interruption (Gas flow controller tripped).

- A capacitor has blown in the matching network.

- Loose connections in the RF chain, get looser with heat.

- Tuning issues: The motor assembly for the load and tune portion of the matching network has been known to fail for alignment between gears and motor failure. Confirm manual control is actually rotating the load and tune caps in the match net.

- Review our ion source manual if you can’t find the problem.