June 2024 Newsletter

Ion beam source video series is now available for old and new users in the industry.

This is our latest news and Tech Tips about ion beam sources.

Ion beam sources can be used for sputtering material or etch. The ion beam source works when a discharge, or plasma, is created inside the source. Ions inside the source are contained using a discharge chamber. The plasma is created using an RF antenna attached to a matching network and generator. The ion beam grids or grid assembly is connected to extract the ion beam and it functions to direct the beam towards the target or substrate.

The ion beam source is operated using our IBEAM power supply. This power supply has a beam module to control the ion energy (voltage) and dose (beam current). The accelerator module controls the ion trajectories. The RF module establishes the plasma and the RFN module connects to the neutralizer.

The latest news and tech tips will provide information to keep your ion beam source operating smoothly.

From 1974 until 2000, Ion Tech Veeco Kaufman manufactured different ion beam sources. Kaufman ion sources are similar but have different grids. Some of our products are compatible with these legacy sources.

Ion beam source video series is now available for old and new users in the industry.

This month we are doing an in-depth look at common feedthrough issues that can occur during the installation and operation of an ion source.

This month we are doing an in-depth look at common grid set issues that can occur during operation and refurbishments. We also discuss the general care of your Moly grids.

This month we are doing an in-depth look at gas flow and chamber pressure issues. Gas flow is required for the operation of an ion beam source. There is lots of useful information condensed for a quick read.

This month we are doing an in-depth look at RFN aging issues. The radio frequency neutralizer (RFN) provides the electrons each RF ion beam source requires. There is lots of useful information condensed for a quick read.

Hello from Colorado! We hope everyone has enjoyed their summer activities with their families and friends.

It was a busy summer at Plasma Process Group, and we are doing our best to work toward shorter lead times for delivery of the common consumables. We owe our successes to our customers. We can’t thank you enough for supporting us.

Why is my water interlock not met?

Many of us in the field of optical coatings and ion beam deposition know that many RF ion sources require water flow for cooling. Water is usually cooling both the source shroud and the RF antenna. They normally run in series with the water supply entering directly through the antenna first, then through the shroud before returning to a chiller or closed loop water cooling system.

The Polyethylene water lines to the RF antenna feed through require electrically isolative tubing to keep your RF power from transmitting to ground through the tubing. Always be aware that this tubing needs to be 7 feet long or longer for both supply and return of the RF feedthrough.

There are a few things to be aware of with your cooling system. First, is making sure your water is non-conductive so RF power can’t get to ground. The goal is to be as close to 7 megaohms as possible. (As measured from the feedthrough to ground). Second, make sure the pH level is as close to 7 as possible to minimize corrosion and electrolysis. Just remember “777”. Lastly, flushing your cooling system biannually or annually at a minimum, to reduce mineral and algae build up in the cooling system.

Some of you may have experienced leaks outside your chamber from the Polyethylene tubing that supplies water to your source for cooling. If your water flow is blocked or restricted the poly tubing can weaken, burst and your source will overheat. If you run the source with no water flow, the same results can occur when the water is finally engaged.

There are other causes of issues like this such as a bad water flow limit switch. We have seen them stay on even when there is no water flow and eventually melt the poly tubing at the feedthrough. Much of this issue can be avoided by following maintenance protocol. We certainly urge you to do planned maintenance over letting it slide till it fails.

Ion source water restriction

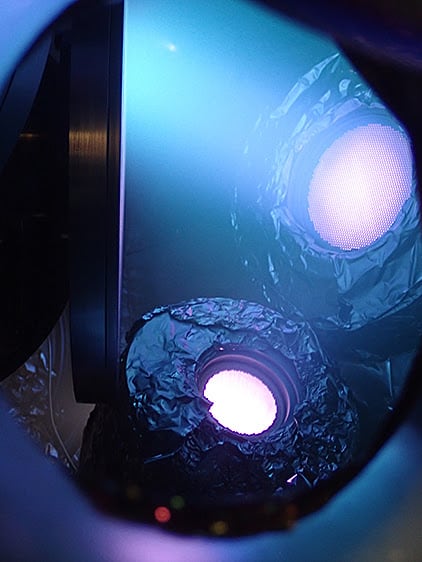

Now for the issue we don’t think you would have thought about. Can you guess what the image above is? If you guessed Polyethylene tubing, you are correct. The poly tubing itself can be a source of failure as well and require maintenance.

This image shows two ends of the poly tubing that were cut off from the entry and exit side of the RF feedthrough connection points of a 16cm RF ion source. The piece on the left with the most restricted center is from the return line side and the one on the right is the supply line.

This restriction is actually not residue or corrosion. It is the poly material itself after many cycles of heat and cold from operation. It has slowly deformed. It can happen if your flow is too low. The Poly will break down and shrink over time. The supply side stays relatively normal because the heat cycles are far less variable or extreme. As you can see, the one on the left is almost completely plugged. In this case the flow switch was working on the system and finally indicated that flow was restrictive enough to send an alarm to the operator that there was not enough cooling to meet the interlock setpoint.

Ion source water restriction

One key point here is to trust interlocks when you are not performing best maintenance practices. Waiting till something fails will commonly create more than one failure in your cooling system. This can lead to ongoing troubleshooting in your system by causing clogs in multiple areas and flow switch failures. In many cases, days of system downtime will follow.

With this Poly tubing issue, we outlined in the above images. The easiest and quickest maintenance step to solve this issue is to simply cut off a half inch of the poly with the ferrule on it and install a new ferrule for reconnection. This literally takes minutes and can keep your flow where it is supposed to be. How often you should do this depends on how proactive you are at doing your recommended maintenance. In this case the tubing restriction took about a year and a half with good maintenance practices.

Because some systems are using individual chillers, and some are using closed loop facility cooling systems, it is important for the maintenance technician to be aware of the issues with conductive water and RF power. Many chemicals are used to reduce algae and adjust pH levels. Sadly, almost all of them will affect conductivity of the water. RF will travel through water if conductive enough and you then lose RF power from your source. Be sure your team is aware of this when looking at adding chemical treatments to your cooling system.

Always follow maintenance protocol on your ion source cooling system. Remember “777”. 7 feet of poly tubing for both return and supply lines to your source RF feedthrough, 7 megaohms for conductivity of your water, and a pH level of 7 for your cooling water. Be sure to clean and flush your systems cooling lines through your source, target assembly and chamber walls. Biannually is recommended for worry free operation.

We hope this segment was beneficial for you and your team. We certainly want you to be successful and maximize your equipment uptime. Please be sure to contact us if you are in need of spare ion source parts, grids or power supplies. We’re happy to help.

Plasma Process Group Techne system operation

We are excited to be attending the SPIE Laser damage conference in Livermore/Dublin, California starting on the 17th of September. If you happen to be at the conference please be sure to look for us. This should be a great conference to attend for Plasma Optik. We look forward to being there.

Today, our Techne has exceeded many of the specifications we had only dreamt of reaching 1 year ago. Especially in the LDT arena. Plasma Optik has a variety of target materials available and is more than happy to discuss your needs when you are ready. Please contact Brett Buchholtz via email at [email protected] or give him a call today at 970-786-6218. He is happy to discuss your project with you.

New Extra Wide Ion Beam Assist

We have some exciting news this month. Plasma Process Group has just officially released our new 20 cm focal length divergent molybdenum grid set for thin film coating companies looking to capitalize on better control in their ion assisted deposition systems.

This new product is a great choice for those manufacturing new state-of-the-art systems, and for those interested in upgrading their older legacy systems that are still in operation today. The benefit of this extra wide beam profile is that it provides a way to cover a much larger area for your assisted deposition processes. It is the perfect grid set for very large area chambers.

The 23 cm Sourcecoupled with this new grid set can provide a wide range of capabilities for a variety of process requirements. The source can be flange or internally mounted, as shown in the image below. The internal mount configuration allows for adaptation to many coating systems. It can be adjusted to maximize your uniformity in your system. Please call us with your ideas.

Longevity In The Industry

Back in early 2006, we were concerned about our customers that were starting to see power supply failures on their legacy systems. We also saw that the type of power supply technology was becoming obsolete. We knew at this point that we needed to bring a new power supply to market. We knew we had to produce a drop-in replacement to our customers with this equipment and keep them going. This decision was a pivotal point in the future of Plasma Process Group.

By 2009, we had officially installed our very first I-Beam 703 Power supply. With the many improvements that have since followed, fast-forward to today and we now provide 10 variations of our I-Beam series power supplies to customers all over the world. We continue to keep our customers running production and supporting R&D.

We continue to manufacture our I-Beam series supplies for both RF and DC applications. With well over 250 I-Beam power supplies in the field, we know there are still others facing these eventual legacy failures so we will continue to be here for you. Call us. We’d be happy to help.

Don’t Forget To Follow Us

In case you missed it, we are now active on LinkedIn, so be sure to follow our page. It is slowly coming online with great information about us and our products. We also intend on sharing some helpful technical tips to those that work with ion source equipment very day. Sign up and stay tuned. We look forward to hearing from you.

Call us now for your ion beam equipment needs at

970-663-6988

Please visit our website at Plasma Process Group. Contact our Sales Manager Dan Bouillez to set up a time to discuss your ion source needs with us.

Visit Plasma Optik for IBS coating services.

Visit Millennium Machining for custom tooling for your vacuum system.

Call 1-970-663-6988

[email protected]

Plasma Process Group

7330 Greendale Road

Windsor, CO 80550 USA

This site uses cookies. By continuing to browse the site, you are agreeing to our use of cookies.

OKLearn moreWe may request cookies to be set on your device. We use cookies to let us know when you visit our websites, how you interact with us, to enrich your user experience, and to customize your relationship with our website.

Click on the different category headings to find out more. You can also change some of your preferences. Note that blocking some types of cookies may impact your experience on our websites and the services we are able to offer.

These cookies are strictly necessary to provide you with services available through our website and to use some of its features.

Because these cookies are strictly necessary to deliver the website, refusing them will have impact how our site functions. You always can block or delete cookies by changing your browser settings and force blocking all cookies on this website. But this will always prompt you to accept/refuse cookies when revisiting our site.

We fully respect if you want to refuse cookies but to avoid asking you again and again kindly allow us to store a cookie for that. You are free to opt out any time or opt in for other cookies to get a better experience. If you refuse cookies we will remove all set cookies in our domain.

We provide you with a list of stored cookies on your computer in our domain so you can check what we stored. Due to security reasons we are not able to show or modify cookies from other domains. You can check these in your browser security settings.

These cookies collect information that is used either in aggregate form to help us understand how our website is being used or how effective our marketing campaigns are, or to help us customize our website and application for you in order to enhance your experience.

If you do not want that we track your visit to our site you can disable tracking in your browser here:

We also use different external services like Google Webfonts, Google Maps, and external Video providers. Since these providers may collect personal data like your IP address we allow you to block them here. Please be aware that this might heavily reduce the functionality and appearance of our site. Changes will take effect once you reload the page.

Google Webfont Settings:

Google Map Settings:

Google reCaptcha Settings:

Vimeo and Youtube video embeds:

The following cookies are also needed - You can choose if you want to allow them:

You can read about our cookies and privacy settings in detail on our Privacy Policy Page.

Privacy Policy