March 2024

Special Edition

Feedthrough issues are the big topic for the March 2024 edition of our tech tips. However, we’d like to first send a very special “Thank you”, to everyone who stopped by our booth at the Photonics West show in San Francisco this year.

It was an exciting show and we got to meet with so many existing, and new colleagues. We look forward to working with all of you in 2024 and hope that your visit was very beneficial.

Also, for those that have a need, if you are looking to upgrade to a new power supply, need a new set of 16 cm grids, or need a spare RFN, we have a few of each of these in stock. Supplies are limited. Please call now.

Tech Tip – Feedthrough Issues

Ion sources require a small group of feedthroughs to operate. Feedthrough issues are less common than issues we see with grids and other ion source components. In this edition of Tech Tips, we will discuss some of these feedthrough issues and provide some insights as to how to avoid them.

If you haven’t delt with a feedthrough issue in the past, we encourage you to review these Tech tips. It will provide you with information about what to look for and hopefully keep your system operational.

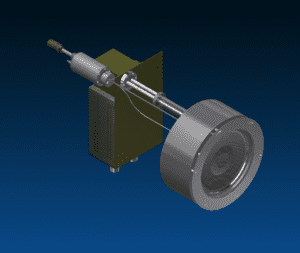

Plasma Process Group — 507178A – 23 cm Interface kit, with feedthroughs for internal mount, 18″ leads w/ 2.75″ CF x2.

Water Cooling Feedthrough Issues, (Non-RF)

Brand new water feedthroughs should last many years. On average, ten years or more as long as your cooling system is circulating clean water. Your water should also have a pH level of 7.0 and be nonconductive.

The pH level is very important. Every water feedthrough has dissimilar metal interfaces. When the pH is too high, it can cause calcium and magnesium buildup in your system. This will eventually lead to clogged water lines.

If the pH is too low, the water becomes acidic and will corrode the water lines much quicker than normal. Adding electrolysis from electrical influences through your system will amplify this effect.

Why monitor pH level?

Stainless steel VCR glands, copper tubing and brazing material are the common metals used in these feedthroughs. When flowing water through these lines, corrosion will occur at these interfaces and at different rates. Typically, the brazing material is the first to corrode and break down.

Make sure you do not use additives in your water unless they are nonconductive. Some additives can be used for biological things like eliminating algae. However, be careful. These can throw off your pH level and your conductivity.

The closer to a pH level of 7, and a conductivity of 7 mega ohms, the longer your system will run without failures. Algae growth will create discoloration in your poly flow tubing. When running water at a pH of 7, algae will likely grow in your cooling system.

Check out our RF source manual for information regarding the required flow rates for your ion source.

Water-Cooling Feedthroughs Issues, (RF source antenna feedthroughs)

One of the most important feedthroughs for your ion source is the water-cooled RF antenna feedthrough. It serves two purposes. One is to provide water-cooling to the RF antenna for consistent RF power distribution during heat cycles.

The second is to provide the RF power required to generate and maintain a plasma inside the discharge chamber. This RF power can be affected by the water being used to cool the antenna.

Why does water conductivity matter?

If the cooling water is too conductive, the RF power can travel through the water to ground. This creates efficiency problems, or RF loss. It can affect the way the RF ion source operates. The cooling water conductivity should be 7 mega ohms or better.

If RF loss occurs, you will start to see your ion source RF power approach maximum output, and then your beam current begins to drop. If you see that you cannot hit your beam current setpoint, it is because your RF power has hit its limit, check your water conductivity.

RF Power Efficiency

Efficiency is key for an ion source to run consistently. RF feedthroughs are known for connection point corrosion on the atmosphere side. High humidity around these feedthroughs can cause oxidation of the silver coating where connections are located. These corroded connection points can cause RF loss.

If you see black or green residue around your RF feedthrough strap connections, shut down the source, lock it out and lightly clean the connection points with a Scotch Brite pad so that the surfaces are clear of carbon build up.

CAUTION: Keep both supply and return poly flow tubing lengths at 7+ ft. in length for your RF feedthrough water flow. Shorter lengths are known to reduce RF efficiency.

DC/Gas Feedthrough Issues

One of the most common issues with these feedthroughs is internal damage from a parasitic plasma occurrence. When a parasitic plasma occurs around this feedthrough, it can burn the lead connectors and insulators. This can cause the DC to short to ground. The insulators can also become coated and cause a direct short to ground.

There have been cases where the lead connections are unintentionally bent during installation. The lead may make contact with ground and short out. This has been known to permanently damage the feedthrough if you attempt to start the source. If one is damaged, it may likely require replacement.

Feedthrough installations

When connecting the source dc leads to your feedthrough, make sure they are not bent toward a ground surface. The leads should be centered in the feedthrough holes once connected. It will be less likely to arc or short out during operation.

The gas line is welded into the feedthrough and typically does not cause issues. However, a gas line can be bent so significantly that the weld or gas line at the feedthrough flange can crack. Though rare, this can create a gas leak, and or an atmospheric leak in the chamber. If a gas leak occurs, you may not be getting gas flow to your source. If your source does not start, be sure to check for this.

During installation of a new DC gas feedthrough, or when you are relocating a gas line in your chamber, be sure to manipulate the gas line carefully. While holding the line from moving at the feedthrough flange during manipulation, you can avoid damage.

Testing Electrical Feedthroughs

Those that have had issues with some of these feedthroughs know the process of testing for a short or checking for good water flow. We use a standard multi-tester that can identify electrical shorts. We measure between the feedthrough flange and the connector.

If a short is detected, it is best to blow out any loose material or flakes from the cable end seals and test again. If it still fails, we recommend replacement. Cleaning any conductive coating from cable end seals or the insulators is not practical.

Testing Water Feedthroughs

Test water flow through the feedthrough if you suspect a water flow issue. Turn off the flow and disconnect the water return line from the return manifold on your system. Place the end of this tube in a bucket. Turn on water flow to the feedthrough and measure LPM to verify it meets the recommended flow rate.

If there is no flow, or there is restricted flow, you can sometimes run a tube brush through the feedthrough water line to clear blockages. If this is not possible, we recommend replacement. Check your RF antenna as well. An RF antenna should be replaced if any water flow restrictions are present. We normally have these in stock.

RFN Feedthrough Issues

RFN feedthrough sizes vary depending on the requirements. We manufacture a number of different feedthroughs for RFN’s but there are a few common issues that can occur when using any version of them.

First, if you suspect or identify a bad cable end seal leak or bad connector, it is more expensive to repair than it is to replace. Our recommendation is to always have a spare on hand. Feedthroughs are not commonly in stock and tend to have long lead times. We encourage you to have a spare on hand for this reason.

Two issues are not with the feedthroughs themselves, but rather the installation of an RFN to the feedthrough. They are lead connection errors, and connection of the gas line to the RFN.

RFN installation on the feedthrough

The lead issues can include the keeper lead connection, and the RF lead connection. When making the keeper connection, it is a common error that the male Deutch pin for the keeper is not inserted into the female connector of the feedthrough. It is instead off to one side and does not make contact. The RFN then does not start when this occurs.

Another lead issue is the position of the RF antenna lead connector. If this connector goes into the standoff tube too far, it can short the RF power to ground. This too will keep the RFN from starting. This female connector should make contact with the male pin. However, it should not go into the standoff all the way.

RFN Gas line on the feedthrough

When connecting the gas line to your RFN, a common occurrence is that the gas isolator rotates and loosens the collector nut inside the discharge chamber. This disconnects the collector and will keep the RFN from starting.

When installing an RFN, use two open end wrenches to connect the gas line. Hold the position of the gas isolator nut so that the gas isolator does not rotate in the RFN while tightening the gas line to it.

Starting Your Source with a feedthrough issue

Many of the common issues outlined above can cause an ion source or RFN not to start. If you have no water flow, you should see a water interlock error and your ion source should not start with this interlock tripped. Did you turn your cooling water on to the source? If so, are you certain that there is good water flow to the source? Check your flow switch or meter to confirm.

RF power shorts to ground will also prohibit your ion source from starting. If there is a short, your source will not tune, and your power supply and/or system should give you an error. Most commonly is an Error – 71. Check you RF power circuit to verify the are no direct shorts to ground from the supply, all the way to the antenna.

CAUTION: Don’t keep trying to restart the source in quick succession. You can damage your power supply by overheating components in the supply. Trying to restart it multiple times in quick succession is not recommended. Allow two or three minutes between attempts. Investigate to locate the cause of the failure to start after 2 or 3 attempts.

How are your connections?

Have you checked to make sure that the RF cable is connected? Are your antenna insulators inside the source coated up? These things can keep your source from starting. In most cases, the RF feedthrough itself is not likely the issue. These feedthroughs typically only fail because of clogged waterlines or a water leak at the stainless steel to copper brazing joints. Electrical issues with the feedthrough rarely occur.

To see some of the feedthroughs we have discussed in this Tech Tip, please check out our interface kits for RF Ion sources to see a general drawing of the configurations we offer. We have many to choose from.

High vacuum pressures around feedthroughs

High vacuum pressure in and around RF feedthroughs can wreak havoc on an ion source and its operation. We have identified things like RF leads in a vacuum chamber that have been wrapped in foil to protect them from being coated.

If you can imagine this for a moment, the foil is closing off access to a volume of gas around the leads that cannot be pumped away. This inadvertently produces a high-pressure regime around the RF leads. In turn, this creates an easy path for RF power to find ground. Always be sure to have adequate pumping around your RF power feedthroughs and ion source.

It is OK to carefully and loosely wrap beaded leads to protect them from process exposure. However, use minimal amounts of foil and place several holes in the foil down the length of the leads to allow for gases to be pumped out.

Feedthrough Life In General

The average life span of a feedthrough that uses water can vary greatly depending on how well you follow recommendations for care. If treated well, they can last 10 years or more. However, we do recommend an occasional inspection for clogged lines. It is good practice to inspect your water lines once every 6 months.

As indicated earlier, the most common failure for the water feedthroughs are water leaks. If you suspect a leak in your chamber, check your water feedthroughs. The most common place for a leak to appear is at the brazed joints in the feedthrough or antenna. These feedthroughs are used in all our RF ion sources. Treat them well and they will treat you right. This said, make sure you have a spare if you do not want your system down.

Questions?

Be sure to reach out to us when you have questions. We certainly want you to be successful and maximize your equipment uptime. Let us know if there are topics you would like to see in a future Tech Tip edition!