November 2023

Special Edition

This month we are doing an in-depth look at RFN aging issues. The radio frequency neutralizer (RFN) provides the electrons each RF ion beam source requires. There is lots of useful information condensed for a quick read. Please take a moment and review our Tech Tips below – and you’ll keep your production system running smoothly and get a greater return on your investment!

Tech Tips – RFN Aging Issues.

Why won’t my RFN start?

The RFN normally works quietly behind the scenes, reliably providing electrons to the downstream environment produced by the ion beam source. If properly maintained, the RFN can operate smoothly for well over 2500 hours. However, it is a sensitive device and if not treated properly, the RFN can be challenging to work with. This article points out the more common issues and provides some preventative maintenance suggestions that keep the RFN happy! And keep your system up and running.

In this edition of Tech Tips we are going to talk about why RFN’s won’t start immediately. There are several reasons for this so we will try to outline them in a bit of detail so those that are refurbishing their own RFN’s have a bit more information about failed attempts and what to do to reduce them.

First, we’d like to give you some data points that are useful in determining your RFN’s are preforming as they should be. A recently refurbished RFN should operate like a new one. Starting time should take less than 30 seconds, but well used should be about 45 seconds to a minute. An RFN should also get from 1500 to 2500 hours of run time before it should be decommissioned for its next refurbishment. Typical keeper voltage on a fresh RFN should be right around 25 volts. While operating an RFN, gas flow should not be above 5 sccm’s. Most should run at 4 sccm’s. How you treat the RFN in process will also determine its life span. Don’t abuse it and it will run well for you.

Flowing Argon

Should I flow Argon during a vent cycle?

Yes. RFNs are very particular about water vapor. What was the base pressure of the system before you turned on the gas? If the chamber isn’t in the low minus 6’s Torr, then there is water vaper in the RFN. Make sure the pressure is 3×10-6 torr or below before turning on the gas. Also, you need to flow the gas for at least 10 minutes before starting the RFN. The collector is one of the two most critical parts of an RFN. It is made of ultra-high purity nickel and should not be reused in an RFN. Once the collector has been used, it has been impregnated with contaminants that can reduce its ability to operate properly. Most used nickel collectors will turn greenish black when they have been run 1500 hours or more in good operating conditions. As seen in the image below, the greenish black at the edges of this photo, is beginning to work toward the center of the collector. As this gets worse, you will see your startup time of the RFN take longer and longer.

Contaminated Nickel Collector

The collector, when being replaced in the RFN discharge chamber, should be very tight in the discharge chamber. If it is too loose, it will make the RFN difficult to start, or it won’t start at all. Keep in mind that Nickel is very soft. Deforming the collector will almost certainly cause issues. Be careful during installation and make sure it is tight and inserted with evenly applied pressure.

The Antenna

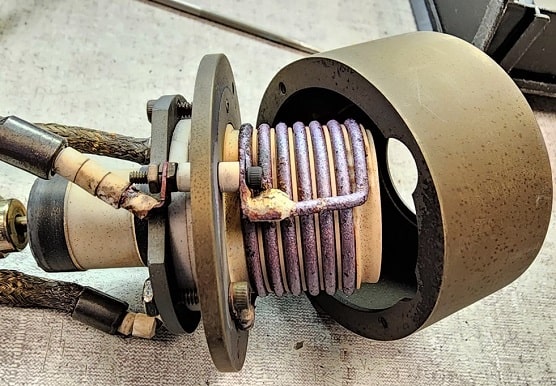

The next RFN aging issue is the antenna. The antenna also plays a big role in how quickly and RFN will start. When refurbishing, the antenna should be very tight with no portions of the coils raised from the discharge chamber O.D.. The shape of the antenna is also critical in that the bend that occurs in it should be smooth and rounded. Refer to the bend just before the first coil in the image below. Start time can be affected by RFN temperature as well. A refurbished RFN should start when cold, warm, or hot without issues. If it does not start in any one of these conditions, it is likely to be a problem with the antenna or a loose collector.

Deformed or out of shape antenna

In the image above, the very end of the copper antenna where it makes the bend to the last coil at the end of the discharge chamber, the antenna is not touching the discharge chamber. Even this small gap can cause starting issues with the RFN. All 7 coils that go around the discharge chamber should be tight against it.

RFN Aging Issues

Below is an image of an RFN that will give you an idea of what we see on occasion when we receive some RFN’s through our refurbishment service program. We offer RFN refurbishment services if you need our assistance. Downtime from RFN struggles can be very costly. That said, this is an example of what a badly treated RFN looks like. Well maintained and treated RFNs will not have debris coming off of the antenna or have sharp corners in the antenna.

Severely damaged or mistreated RFN

Proper Cooling

Should I cool the RFN before venting?

Yes. It is always strongly advised that you let the RFN cool 15 to 30 minute before venting your chamber. The longer you wait, the better. Always flow 5 sccm’s of Argon to the RFN while vented and during venting your chamber. This keeps water vapor out and allows the RFN to cool even further while vented. Some other common issues with RFN’s include a loose collector nut. When installing your RFN, use two open end wrenches to tighten the gas line fittings at the back of your RFN. Always avoid rotating the gas isolator during this process. If you don’t, you risk rotation of the collector nut inside the discharge chamber and loosening it. Sometimes a damaged gas line or gas isolator can cause the RFN not to start. Because your gas flow isn’t getting to the discharge chamber. Check your gas line and your gas isolator for a leaks during your refurbishment process.

Other Tips

One final though less frequent failure is the RFN pin connections at the feedthrough. These leads can sometimes be installed incorrectly. Be sure you see the pins actually slip into the receiving connector before tightening the thumb nut to hold them in place. If you miss one, your RFN will not start. Also be sure your RF cable for the RFN is connected to the RFN matching network. Though rare it happens to the best of us. If your refurbishments are successful and done properly, no matching network tuning should be required. An occasional C1 fine tune adjustment may be needed to simply reduce reflected power to less than 2 mA once the RFN warms up in the chamber for the first time.

We hope this in-depth segment about RFN aging issues was beneficial for you and your team. We certainly want you to be successful and maximize your equipment uptime. Let us know if there are any other topics you would like to see in a future Tech Tip segment!